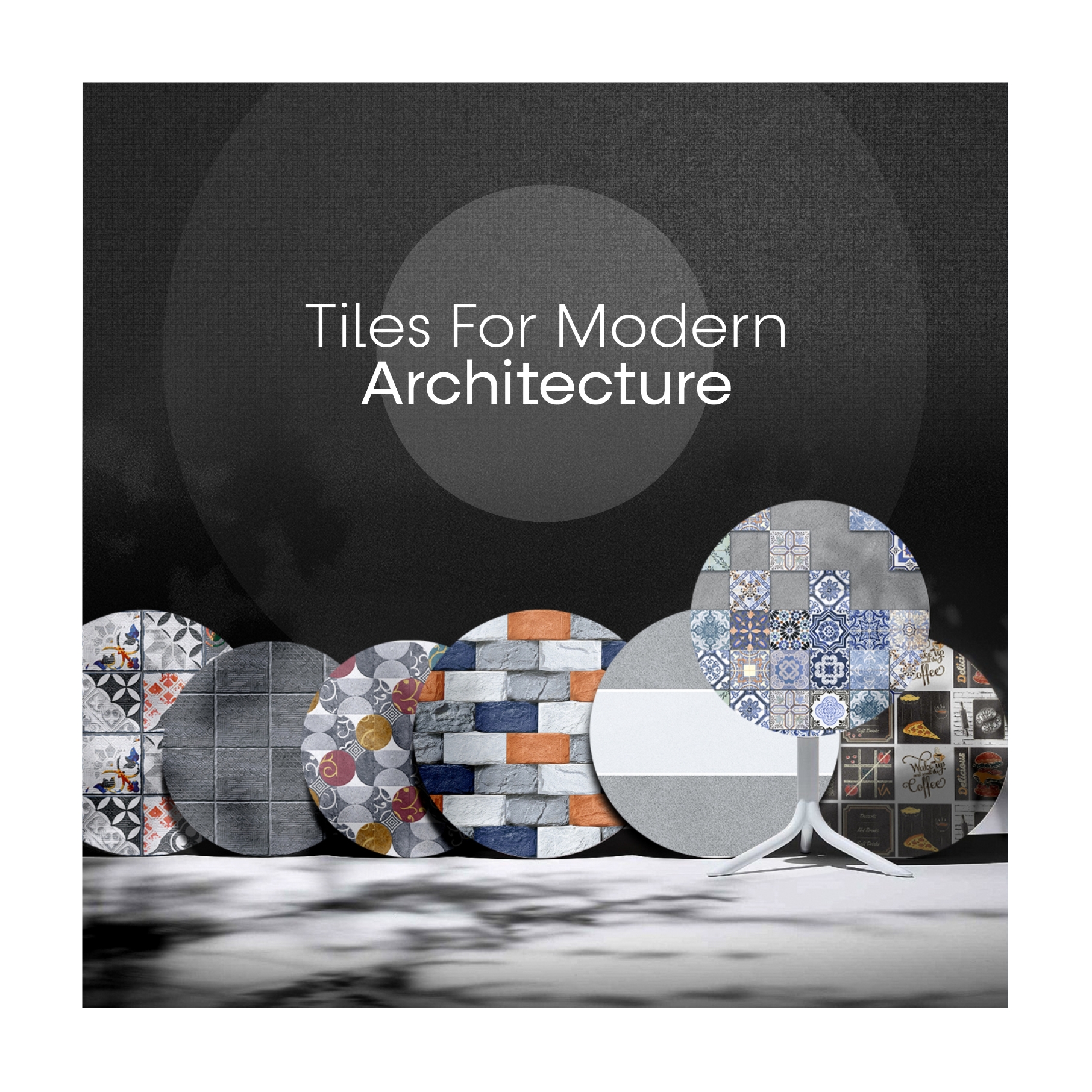

Artistry, Quality, Innovation.

Finishes We’ve worked with

SPHERE OF BUSINESS

The Company Is Committed To Practicing Environmental Stewardship Throughout Its Manufacturing Chain From Product Design And Ecient Operations Processes And To Playing An Active Role In Building A Better Community By Enhancing The Surrounding Environment .

Organization’s Activities Improve Energy Eciency, Reduce Pollution, Enhance.

Tile Tales

Eco-Friendly

High Reflection Glaze

Low water Absorption

Replacement For Italian marble

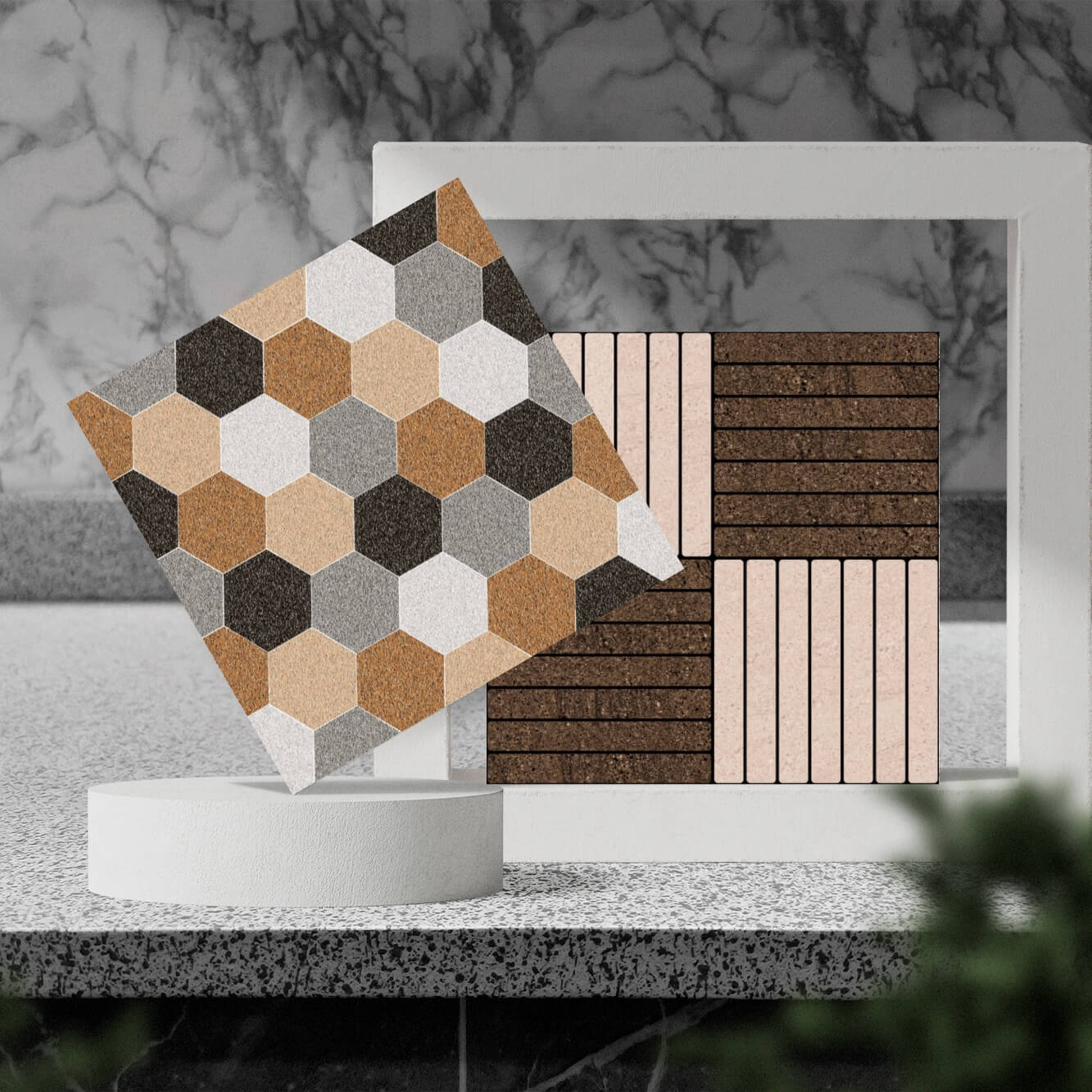

Our Collection

Process

Ceramic Tile Manufacturing Process.

Ceramic tiles are made from a variety of raw materials, including clay, feldspar, silica, and other minerals. These materials are mined, crushed, and ground into a fine powder. The powder is then mixed with water to form a slurry, which is poured into molds to create the desired shape and size of the tile.

Once the tiles are molded, they are dried to remove excess moisture. This is typically done in a kiln or dryer, where the tiles are heated to a high temperature to evaporate the water. The drying process can take several hours or even days, depending on the size and thickness of the tiles.

After the tiles are dried, they are coated with a glaze, which is a thin layer of liquid glass. The glaze is applied to the surface of the tile using a spray gun or roller, and then the tiles are fired in a kiln at a high temperature to fuse the glaze to the surface. This gives the tiles their characteristic glossy finish and makes them resistant to water and stains.

The final step in the ceramic tile manufacturing process is firing. The tiles are placed in a kiln and heated to a high temperature, typically around 2000 degrees Fahrenheit (1100 degrees Celsius). This process hardens the tiles and makes them durable and long-lasting. The firing process can take several hours or even days, depending on the type of tile and the desired finish.

Gallery